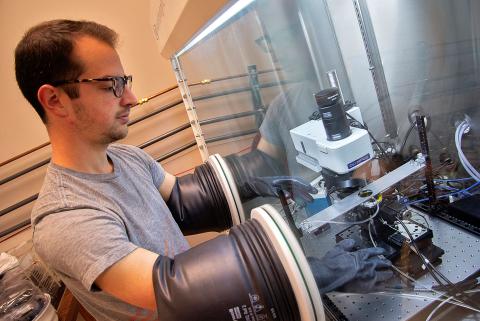

Will Burg is a recent Ph.D. alumnus who devised techniques to introduce controlled twist angles between atomically thin carbon sheets, known as graphene, and observed spectacular properties, like superconductivity, in moiré patterns of graphene, a material that is not a superconductor under normal conditions. These discoveries can potentially lead to new quantum devices for computation.

Burg’s dissertation, “Collective Quantum States in Twist Controlled Graphene Heterostructures” was awarded the 2023 Michael H. Granof Award – the Graduate School’s most prestigious honor. The Granof Award, which is underwritten by the University Co-op, was established to recognize exceptional work by doctoral students and encourage the highest levels of scholarship, research, and writing. The annual winner receives a $10,000 prize.

In recent years, the twist angle between vertically stacked, two-dimensional materials has come to the forefront in the field of solid state physics as a key parameter for modifying the characteristics of 2D heterostructure devices and tuning the strength of electron-electron interactions. Dr. Burg’s dissertation discusses three heterostructures in which the twist angles between layers are controlled to enable interactions and probe collective states.

Burg is the first author of 8 refereed journal and conference papers and a co-author of 18 more, many of which are in high‐impact journals in his field. With a citation count exceeding 900, including nearly 250 in 2022 alone, his work is rapidly gaining recognition.

Leonard Franklin Register, the J. H. Herring Centennial Professor of Engineering at the Chandra Family Department of Electrical and Computer Engineering at UT, says this about his work: “The contributions of William Burg’s dissertation are many, groundbreaking, and widely recognized by those in the field, as evidenced both by acceptance for publication and presentation in the best refereed journals and venues and by numerous subsequent citations. His research has focused not on pushing the envelope of existing technologies but, instead, on trailblazing pathways to potential new technologies via demonstration of possible new physical mechanisms of operation.”

Will Burg is now a hardware engineer at Apple and took time away from his work to answer questions for us.

How would you explain the key findings of your dissertation to a non-specialist audience?

In typical electronic materials, electrons are generally fast-moving and fly past each other too quickly to interact with one another. By applying a small twist angle between two adjacent graphene layers, we were able to create an electronic structure that slowed the electrons to nearly zero velocity. At these low speeds, electrons can strongly interact with each other and give rise to exotic states, such as superconductivity.

What first attracted you to the world of electronic materials and quantum properties? How did you know you wanted to pursue research in this area?

I first encountered graphene and other two-dimensional materials while volunteering for a research group as an undergraduate. At the time, the field was still relatively new and there seemed to be a lot of physics and potential applications still to be discovered. I enjoyed the research as an undergrad and figured, why not continue doing that in grad school?

I understand that you helped develop new techniques that enabled a new class of materials – moiré crystals. Can you tell me more about what led you to that advancement?

The core techniques for fabricating moiré crystals were actually developed by a previous member of my research group and subsequently adopted by the rest of the field, so I owe a lot to him. Fortunately, I was able to build on that foundation to improve device quality and complexity. A lot of that came from trial-and-error and small refinements over the years, but the biggest single contributor was a motorized, computer-controlled system I designed and built to semi-automate the fabrication process, which had been largely manual. This helped remove a lot of the variability in twist angle control and improved yield, which was really the key to making these more complex, multi-layer devices possible.

Did you encounter any significant challenges in your research? If so, what were they and how did you overcome them?

The primary challenge underpinning my research was the difficult and time-consuming process of fabricating these complex, low-yield devices, which required very high precision and often took weeks to make. Persistence was of course important, but I found that most important was a consistent focus on innovating, or at the very least optimizing, the existing processes. Even when making improvements to some part of a process took more time in the short term, it typically saved time and improved results in the long term.

What are you currently doing and what are your plans for the future?

I am currently an engineer at Apple, working on OLED displays. Most of my work falls at the intersection of hardware and software engineering. I tend to not have set plans for the future, I just try to continue working on interesting problems and learning new things and see where that takes me!